This leadership team understands the 503B market is laden with pitfalls and dangers. Because of that, QUALITY is the most important thing we can offer our customers and patients. So, how does Wells Pharma maintain the highest quality standards?

In addition to producing products in a sterile environment and using highly-trained Pharmacy Technicians to perform production under the direct supervision of a Registered Pharmacist, Wells Pharma is committed to making sure that every product that leaves one of our facilities is quarantined until testing results show that the product is Sterile, Potent and the Endotoxin testing is confirmed. Every batch of drug product is tested for release criteria by an outside, independent laboratory.

Prior to the commercial production of any drug products, WPH performs Stability Studies in triplicate to validate the process of preparing the drug. These three batches produced for the Stability Study are tested not only for Sterility, Potency, and Endotoxins, but also for Particulate Matter, pH Level, Identification, Appearance, and Container Closure. The stability study results allow for the proper assignment of BUD, (Beyond Use Date), which is an important factor for our customers.

For the stability studies, Time 0 is considered the first day of testing by the independent laboratory. Additional test intervals are generally at 30 days (T30), 60 days (T60), 90 days (T90), and 120 days (T120), after production. However, some products, which are less stable, will have other defined time points. Assignable BUD is established when, at the end of the stability study, the product is still within the required specification range for each test. It is only after the successful completion of the stability study that the product will receive a BUD for the defined test interval.

After the stability study is complete and the product goes into production, every subsequent batch has samples retained, (for batch-specific testing), which are submitted to the lab electronically and shipped over-night. Testing is typically completed within two weeks of the acceptance of the samples by the laboratory. While the lab conducts the testing, the product is quarantined in an access-controlled area by Quality Control (QC).

Once the lab results are verified by QC, a process is followed to verify that the specific product “lot” meets the acceptance criteria. Additionally, environmental conditions, label verification, visual inspection, and release testing must meet pre-approved specifications for that product. Final approval for batch/lot release is performed by QA management. This extensive process for releasing a batch/lot is thorough because QC and QA verify that the SOP’s are followed as it relates to regulatory requirements for compliance for a 503B facility.

While it would be easy (and cheaper) to do “spot checks”, testing only X-number of production batches, Wells Pharma tests EVERY batch, and nothing is shipped to our customers until it has been through our rigorous Quality process. Our customers must be certain that, when they administer a drug to a patient, the drug is safe to use. And they must have faith and trust in Wells Pharma and our manufacturing processes and controls.

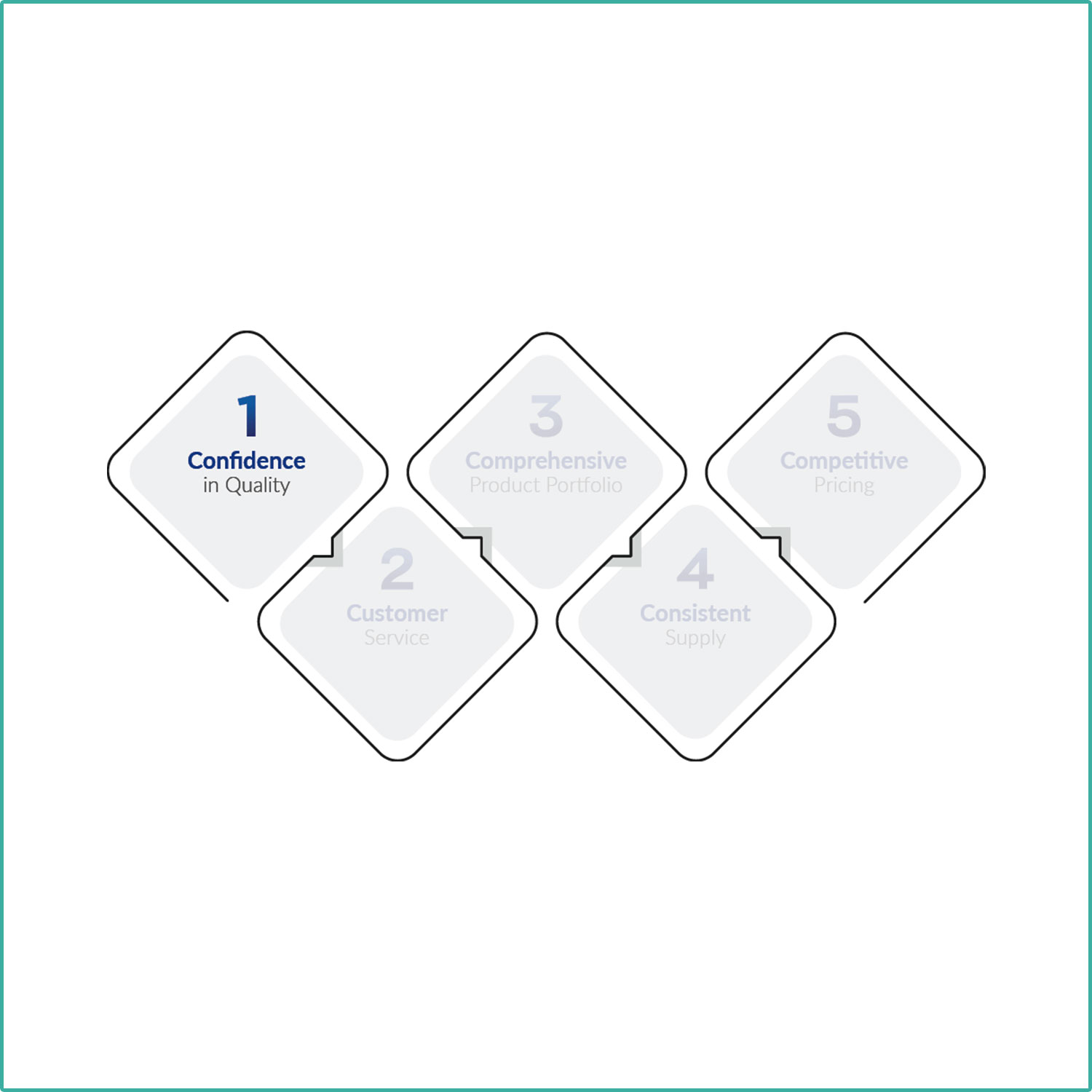

In short, our customers must have Confidence in the Wells Pharma Quality…

Please visit our website, and “C” the Wells Pharma difference for yourself!